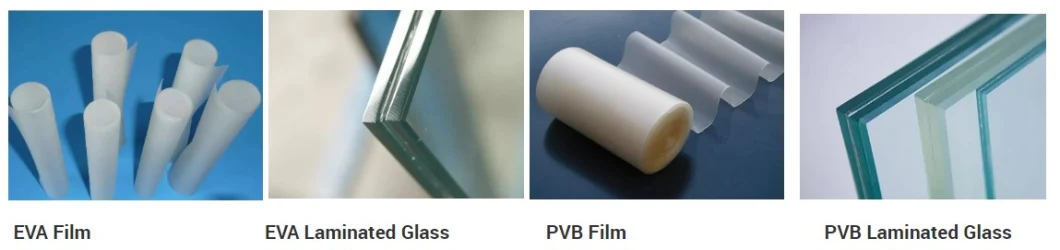

EVA/PVB Laminated Glass Cutting Line Laminated Glass Cutting Machine Laminated Glass Cutter Laminated Glass Cutting Table Laminating Glass Cutting Machine

Overview Product DescriptionEVA/PVB Laminated Glass Cutting Line Laminated Glass Cutting Machine Laminated Glass Cutter

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | GS-LM-3826 |

| After-sales Service | Support Online, Video Technology Support |

| Cutting Speed | Cutting Speed: 0 ~ 100m / Min |

| The Maximum Size of Cuttable Laminated G | 3700mm |

| Minimum Size of Cuttable Laminated Glass | 200X200mm |

| Cutting Thickness | 3+3mm-10+10mm Laminated Glass |

| Transport Package | Seaworthy Packing |

| Specification | 4000kg |

| Trademark | Glasino |

| Origin | China |

Product Description

EVA/PVB Laminated Glass Cutting Line Laminated Glass Cutting Machine Laminated Glass Cutter Laminated Glass Cutting Table Laminating Glass Cutting Machine

Characteristic

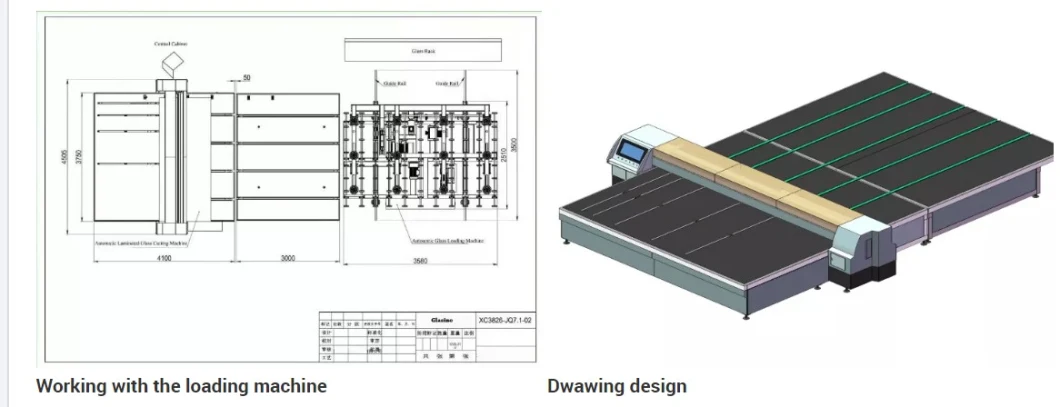

1. Easy operation, high cutting precision2. International standard steel with perfect surface treatment 3. Key area was annealed and milled, which ensures the high stability and intensity4. Cutting and breaking pressure adjustable5. Far-infrared heating temperature and heating time adjustable 6. Machine includes three sections and bridge frame7. The first two sections are glass loading and transfer area with auto location system and mechanical location device 8. The third section has functions of glass stretch and glass break9. Bridge frame is the center of the cutting system, which includes up and down double cutters, upper clamp and film far-infrared cutting.

Technical Parameters

| Machine Name | Laminated Glass Cutting Machine |

| Model | GS-LM3826 |

| Max. Glass Sheet Size | 3700x2600mm |

| Min. Glass Cutting Size | 200x200mm |

| Cutting thickness | 3+3mm-10+10mm laminated glassFilm thickness 0.38-1.52mm (PVB, EVA) |

| Straight line parallelism | ≤±0.20mm/m |

| Cutting speed | 0 ~ 100m / min |

| Equipment weight | 4000kg |

| Dimensions | 7100x4500x1500mm |

Main Parts

The main electrical part(1) Controlled by PC computer, Microsoft Windows interface(2) Voltage: 415V/380V/50HZ, equipment with voltage regulator(3) Motor: Yaskawa servo motor (4) Encoder: Omron (5) Controller: American industrial computer (6) Heating tube: short-wave gold-plated infrared heating tube (lifetime 5000H)(7) Proportional valve: Japanese SMC (8) Low-voltage electrical appliances: Schneider, France

Our customers

Packaging & ShippingCompany Profile

Jinan Glasino Technology Co, Ltd founded in 2003, is the high-tech enterprises specializing in the production of CNC glass cuttingmachine,insulating glass machine, curtain wall glass machine, market share ranks first in the same line. Main products are:Laminated glass cutting machine, Automatic glass cutting line, Multifunctional glass cutting machine, Insulating glass production line, Automatic insulating glass CNC sealing machine, Aluminum spacer bending machine, Desiccant filling machine etc, full set processing machine for insulating glass.We have passed European CE certificate, Switzerland SGS certificate, ISO 9001: 2008 quality control system,win good reputation from domestic and international customer. Outstanding quality is the basis of brand. Satisfying service is the guarantee or brand. Perpetual innovation is the soul of brand.Glasino people will continue making efforts and persist in taking the quality as the life of the enterprise. Continuously improve the production management level, research and develop more advanced tecnology to meet the needs of the market. Glasino will work with you to create a brilliant future.

ExihibitionItaly VITRUM EXHIBITION MEXICO MACHINE EXHIBITION INDIA EXHIBITION CHINA EXHIBITION

Why Chose Us?

Related Products

-

![CE Certificate USA Market Hot Melt Gradient/Pdlc/EVA/PVB/Sgp Film for Glass Laminating Interlayer]()

CE Certificate USA Market Hot Melt Gradient/Pdlc/EVA/PVB/Sgp Film for Glass Laminating Interlayer

-

![CE Certification Laminated Glass Oven PVB EVA Glass Laminating Machine Glass Making Machine]()

CE Certification Laminated Glass Oven PVB EVA Glass Laminating Machine Glass Making Machine

-

![EVA Laminated Glass Smart Glass Switchable Glass Privacy Glass with CE SGCC Certificate]()

EVA Laminated Glass Smart Glass Switchable Glass Privacy Glass with CE SGCC Certificate

-

![Magic Glass Windows Glass Pdlc Lamination Film]()

Magic Glass Windows Glass Pdlc Lamination Film