Phone LCD Glass Laminator Laminating Bubble Remover

Overview Product Description This equipment adopts a special heating tube for heating and automatic door opening. It is

Send your inquiryDESCRIPTION

Basic Info

| Automatic Grade | Automatic |

| Installation | Vertical |

| Driven Type | Electric |

| Function 1 | Autoclave (Removes Bubbles) for Big Screen |

| Function 2 | Ocf Sca Cof Defoaming Remover |

| Application 1 | Electrical Tool Set Computer Tool Kit, |

| Application 2 | Bubble Remover for Big Screen |

| Voltage | 380V/220V, 220V |

| Weight | 1000kg |

| Keyword | Bubble Remover Machine |

| Transport Package | Wooden Packing |

| Specification | W1260*D1600*H2080mm |

| Trademark | HonMa/OEM |

| Origin | China |

| HS Code | 8501109190 |

| Production Capacity | 5000PCS/Month |

Product Description

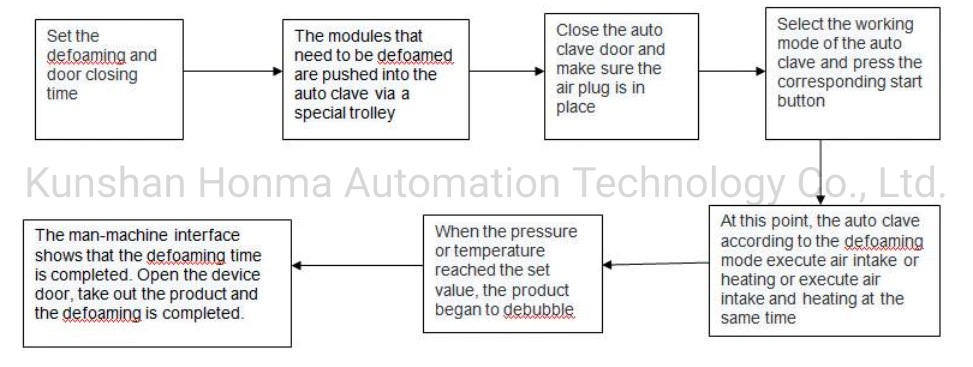

This equipment adopts a special heating tube for heating and automatic door opening. It is mainly used in the production line of liquid crystal modules to remove the bubbles generated in the process of polarizer and LCD glass, ITO film and glass bonding, 3D glass bonding, FPC bonding, etc. by using pressure and temperature.1. Internal material of chamber: SUS304 # stainless stee.

2. Internal device: adopt layered mode, with 2 layers equally divided.

3. Mitsubishi PLC control system, with 7-inch Willen color human-machine interface, can set permissions for parameter modification.

4. Manual exhaust: in case of sudden power failure, the gas inside the tank can bedischarged through the valve.5. Working pressure range: working pressure 0.5~7KG/cm2

6. Temperature range: room temperature - 100 ºC can be adjusted, and the temperaturefunction can be opened and closed independently.

Product Parameters

| Water-cooled deforming machine | 3D glass deforming machine | 85 inch deforming machine | |

| Model: | HMTP-B1000-S1 | HMTP-B800-Z18 | HMTP-T1600 |

| Main application | Fingerprint identification fitWatch fitTouch Panel fit | It is especially suitable for the elimination of bubbles produced by thecombination of 3D curved glass andtextured diaphragm, the elimination of bubbles producedby the combination of unibody PC injection parts anddiaphragm, and the solution of bubbles produced by theblind hole sealant of touch panel module. | It is mainly used in the defoaming of large-sizeLCD screen |

| Equipment description | Adopt water cooling circulation system, temperatureuniformity can reach ±1ºC | ||

| Pressure classification: | 0.1-1.0Mpa / 0-1.8Mpa | 0-1.8Mpa | |

| Common size: | φ800*1200mm , φ1000*1200mm | φ 800*1200mm ; φ 1000*1200mm | |

| Temperature range: | 0 ºC-150 ºC | ||

| Temperature uniformity: | 120 ºC | ±2 ºC; | |

| Working mode: | Pressure first, heating upHeating up first, pressurizingSimultaneous heating and increasing pressure | ||

| Pressure Mode: | |||

| Intellectual control software copyright | Intellectual control software copyright | ||

| National inspection certificate, quality, safety and reliability | Pressure vessel quality certificate | ||

| Good effect of SUS304# | |||

| Intelligent piecewise control | |||

| Main accessories | |||

| Program Control: | Mitsubishi | Mitsubishi | |

| Pressure Mode: | Fuji | Fuji pressure gauges and sensors in Japan | |

| Electrical part: | Fuji, Japan | Fuji, Japan | |

| Pneumatic part: | Japan SMC | Japan SMC | |

| Man-machine interface: | Taiwan Wheelen | Taiwan Wheelen touch screen | |

| Fuji temperature control meter of Japan; |

Goods will be packed in strict safety before transportation. As shown in the figure above. Try to ensure that no damage occurs in the course of transportation. Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW, FOB or CIF.The specific way can be confirmed in the process of communication and confirmation of the order.Our Advantages

1. A factory owing 15 years experience for research and production machines, and the accessories are all using famous brand.2. We own experienced R&D teams.3. A full range of machine patents and software right.4. Timely delivery, 15 minutes to shanghai port.5. Professional after-sale service, Email will be reply in 1 hours.6. Professional technical support, such as Site installation or video support, technical training, commissioning.7. One year guarantee and lifelong maintenance.

FAQ

| Q: Are you trading company or manufacture? |

| A: We are both manufacture and trading company. We have over 15 years' professional experience as an industrial drying equipment manufacturer. |

| Q: Do you provide OEM ODM service? |

| A: Yes. We have our own R&D team to customize your machine plan. |

| Q: How about the production capacity of your company? |

| A: Our factory covers area about 5000M2 and produces machines 1500+ sets per year. |

| Q: How could we trust you and your company for the first transaction? |

| A: Our company has more than 15 years professional experience. We cooperate with a lot of big customers, such Panasonic, Threebond, Hisilicon, HUAWAEI. Welcome to our company and watch our plant production condition any time. |

| Q:What kind of certificate do you have? |

| A:CE&ISO |

| Q: How long is your warranty? |

| A: One year after the arrival of the goods. |

| Q: What about your delivery time? |

| A: Normally within 25 working days against down payment. |

| Q: What about the package of your export product? |

| A: We use standard export wooden case with foam inside. |

| Q: Can we visit the factory? |

| A: Yes, welcome. We have two factories, one is in Kunshan, Jiangsu Province; The other is in dongguang, Guangdong Province. |

Related Products

-

![UL Certified 82% Clear Switchable Privacy Window Film Frosted Smart Glass Pdlc Magic Electrochromic Electronic Electric Foil Opaque Films]()

UL Certified 82% Clear Switchable Privacy Window Film Frosted Smart Glass Pdlc Magic Electrochromic Electronic Electric Foil Opaque Films

-

![Wholesale Selfadhesive Switchable Smart Film Pdlc Film]()

Wholesale Selfadhesive Switchable Smart Film Pdlc Film

-

![French Lace Fabric Elastic Stretch Dress Fabric Nylon Beautiful Soft Material Decorative for Lingerie or Lace Ladies Dresses]()

French Lace Fabric Elastic Stretch Dress Fabric Nylon Beautiful Soft Material Decorative for Lingerie or Lace Ladies Dresses

-

![Display Best Mobile Display Bubble Remover Machine for Mobile]()

Display Best Mobile Display Bubble Remover Machine for Mobile